ЧТО ВЫ ИЩЕТЕ?

Популярные запросы :

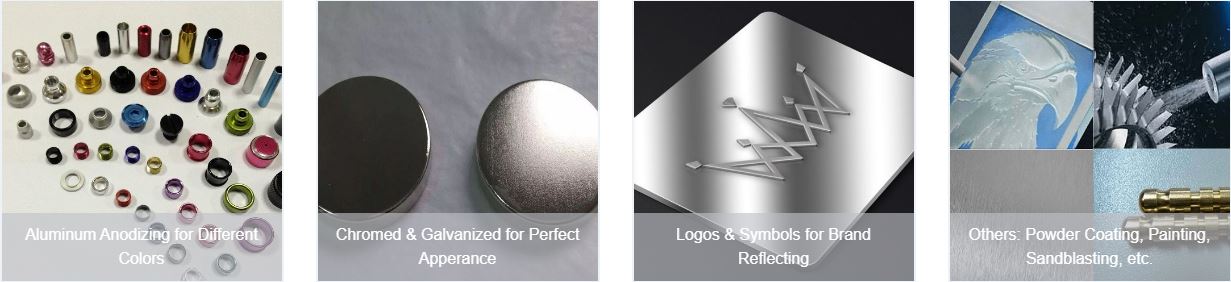

услуги микрообработки деталей, обработанных на станке с ЧПУ услуги по индивидуальной механической обработке индивидуальная обработка с ЧПУ OEM быстрая обработка прототипов с ЧПУ на заказ деталей из нержавеющей стали услуги высокоточной настройки/фрезерования с ЧПУ услуги по индивидуальной обработке, сертифицированная по стандарту ISO обработка с ЧПУ Прецизионные токарные и фрезерные детали Услуги по обработке титановых сплавовЧТО ВЫ ИЩЕТЕ?

Популярные запросы :

услуги микрообработки деталей, обработанных на станке с ЧПУ услуги по индивидуальной механической обработке индивидуальная обработка с ЧПУ OEM быстрая обработка прототипов с ЧПУ на заказ деталей из нержавеющей стали услуги высокоточной настройки/фрезерования с ЧПУ услуги по индивидуальной обработке, сертифицированная по стандарту ISO обработка с ЧПУ Прецизионные токарные и фрезерные детали Услуги по обработке титановых сплавов

ПОДПИСАТЬСЯ НА НАШУ РАССЫЛКУ

ПОДПИСАТЬСЯ НА НАШУ РАССЫЛКУ